High Quality Sheet Pile Production Line – Metal sheet pile machine production line – Thomas

High Quality Sheet Pile Production Line – Metal sheet pile machine production line – Thomas Detail:

The long history of sheet pile can be traced to Roman times when boards are processed into arrow shape to prevent landslide. Both ends of sheet pile has jogged latch whose prototype is board sheet pile. After many times of modification in material and shape, “steel sheet pile” becomes the mainstream product.

Steel sheet pile is designed and developed for channel revetment, landslide prevention and temporary cofferdam. Depending on rich accumulation of experience in cold bending roll forming technology, we manufacture steel sheet pile with high quality and accuracy.

The steel sheet pile machine is an equipment used to produce steel sheet piles by cold rolling forming technical method from the steel coils. The sheet pilling production line is designed based on the cross-sectional dimensions of its final productions, and can manufacture the final productions within the tolerance range.

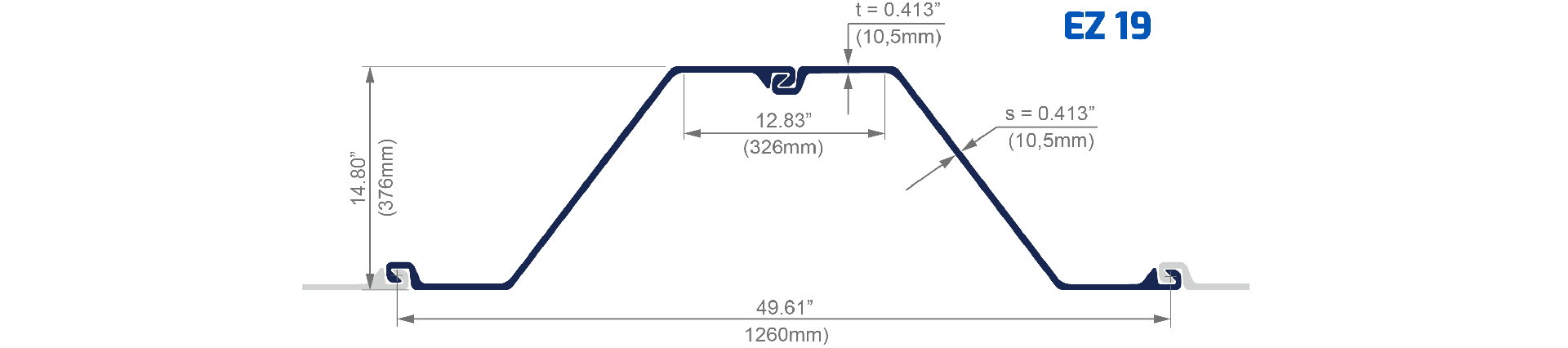

1.Drawing of the profile :

(Machine can be customized according to your needs, the following picture is the drawing provided by our customer, for reference only.)

2. Finished Production for reference :

3.Working process :

Coil Loading → Decoiler → Straight Head → Pinch Leveling → Head and Tail Shear Butt Welding → Entrance Guided Leveling → Roll forming → Cut to Length → Conveyor Roller Table → Dial Out → Chain Transfer

4. Machine Pictures:

5. Machine Details :

|

N.O. |

Name |

Quantity |

Remark |

|

1 |

Decoiler car |

1 |

Material storage platform included |

|

2 |

Decoiler |

1 |

Single arm suspend |

|

3 |

Straight Head Pinch Leveling |

1 |

Full hydraulic control; 2-roller pinch, 5-roller leveling |

|

4 |

Shear Butt Welding |

1 |

Hydraulic shears, including butt welding trolley |

|

5 |

Roll Forming |

1 |

The first 6 spindles are Φ200mm; the rear 12 spindles are Φ150mm; the main motor is 160KW×3 |

|

6 |

Saw |

Friction saw; sawing motor 132KW; moving motor 55KW |

|

|

7 |

Flying Saw Backward Track |

1 |

30m saw backward track |

|

8 |

Material Arrange Device |

1 |

Hydraulic shift |

|

9 |

Chain Transfer Device |

1 |

Driven by motor, 3 racks, 5 meters each |

|

10 |

Under Ground Buried Set Up |

1 |

|

|

11 |

Electric Control System |

1 |

|

|

12 |

Hydraulic System |

1 |

|

|

13 |

Rollers |

2 |

6. After-sales service :

1) . User manuals / videos on installation, adjustment, setup and maintenance of the machine will be provided.

2). The machine is with Wi-Fi function, our technicians will help to work if the machine has a problem.

3). when the borders are open, we will send technicians to your factory for training. (The cost is paid by the seller.)

4). Warranty 2 years (Excluding man-made damage)

5). Delivery time: 90 working days.

6). Machine price: contact us.

7.About Us :

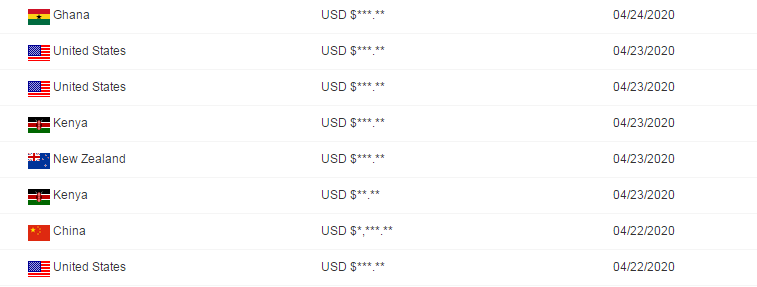

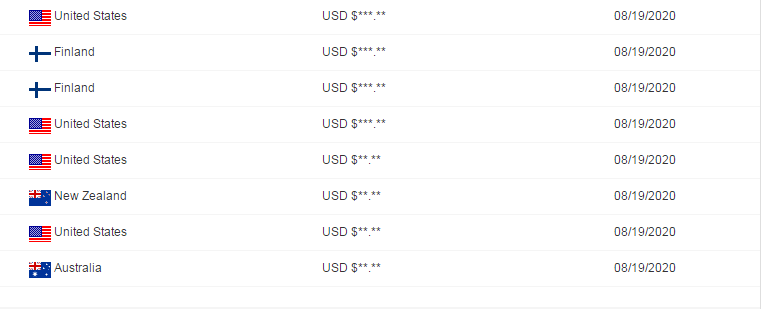

8.Transaction history :

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to just about every client, but also are ready to receive any suggestion offered by our buyers for High Quality Sheet Pile Production Line – Metal sheet pile machine production line – Thomas , The product will supply to all over the world, such as: Slovak Republic, Bhutan, Cancun, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We've got established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance might be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!