Original Factory Silo Body Corrugated Plate Production Line - Grain bin silo stiffener making machine – Thomas

Original Factory Silo Body Corrugated Plate Production Line - Grain bin silo stiffener making machine – Thomas Detail:

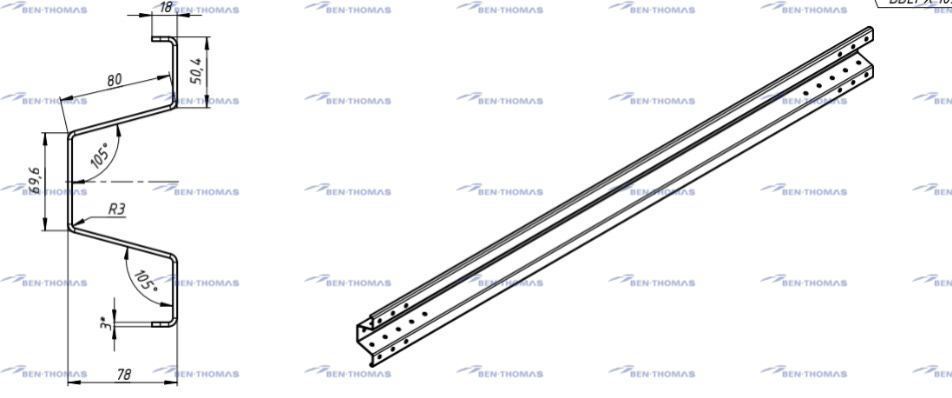

1.Drawing of the profile of the silo stiffener:

(Machine can be customized according to your needs, the following picture is the drawing provided by our customer, for reference only.)

2.Finished Product:

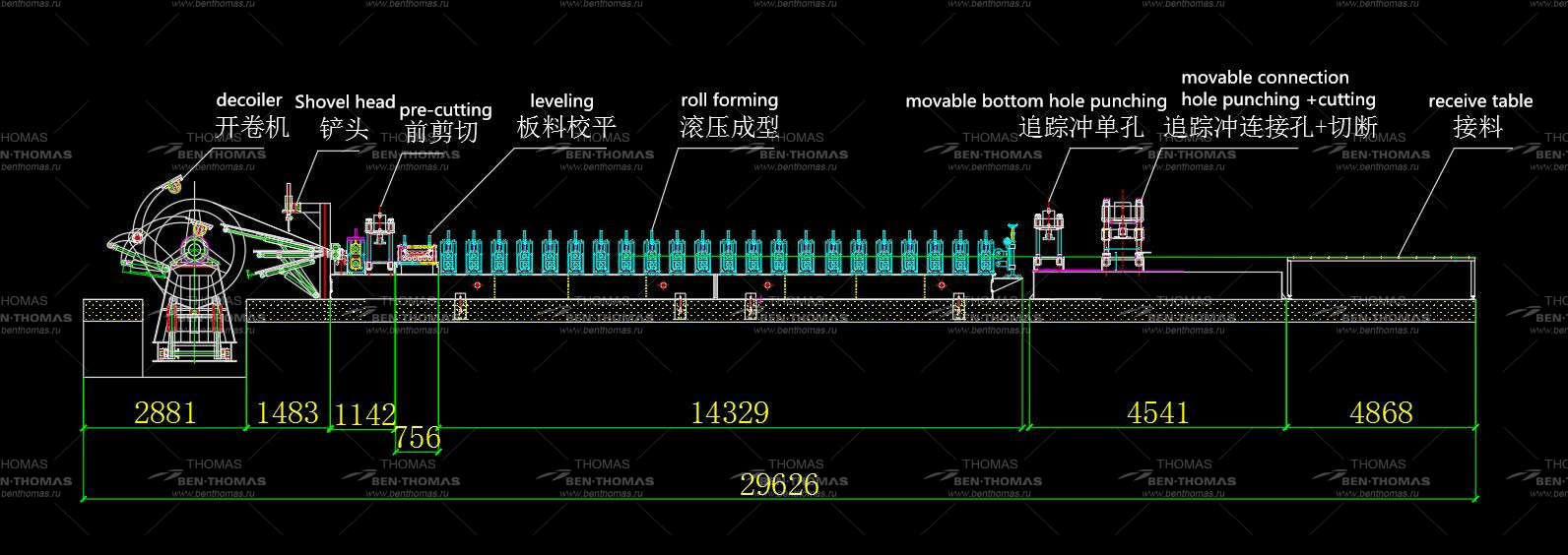

3.Working process of the production line:

Hydraulic unwinder —– Shovel device (auxiliary feed + leveling) —– Pre-cutting – Main forming machine —– Telescopic support – Hydraulic punching device – Moving pallet —– CNC bending Hydraulic – Hydraulic cutting – receiving table

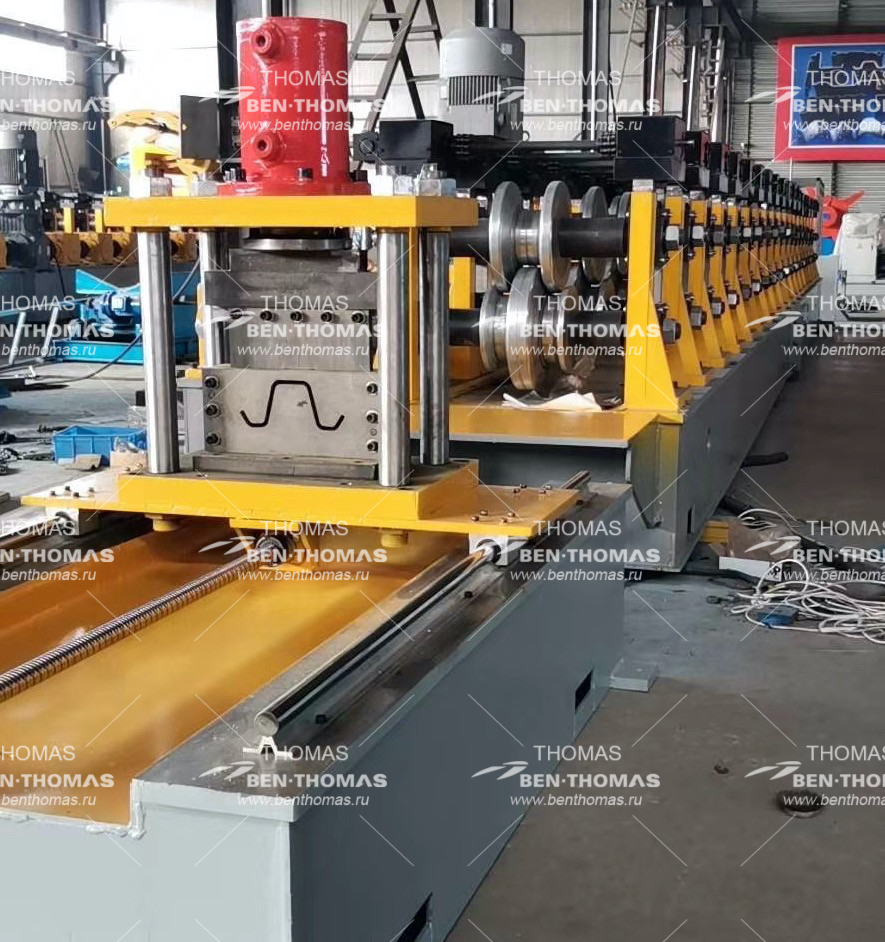

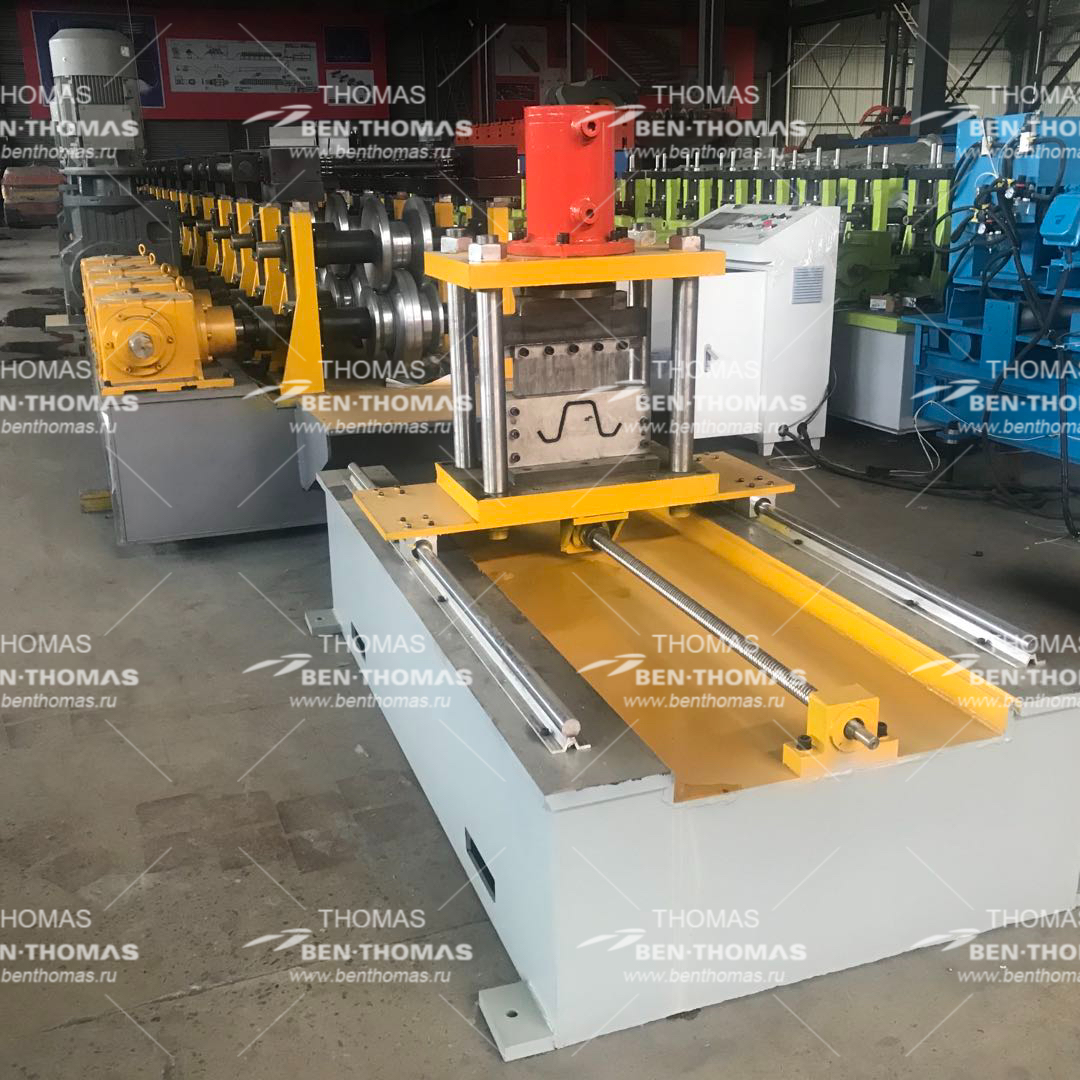

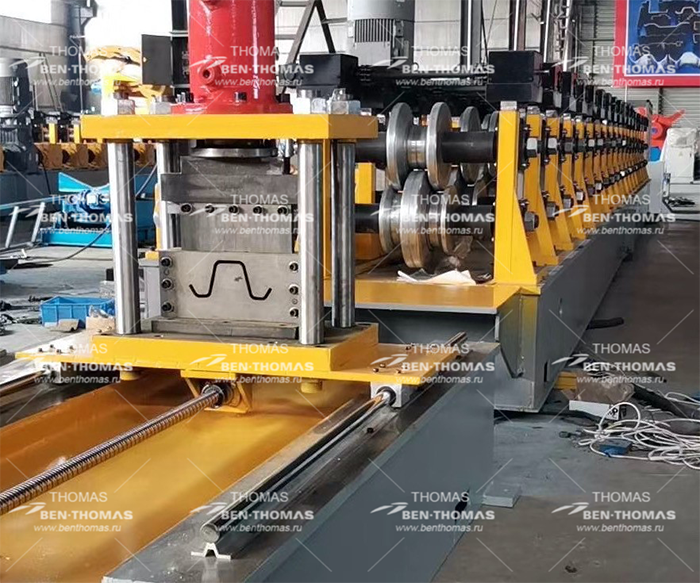

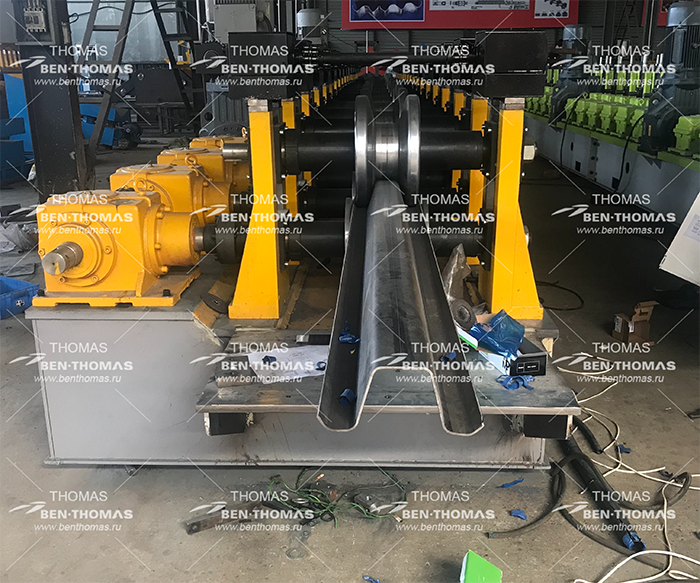

4. Machine Pictures:

5. Machine Details :

|

Description |

||

|

Production name |

Silo Stiffener Forming Machine |

|

|

Machine floor area |

About 25.5m*2m(L*W) |

|

|

Feeding direction |

left in, and right out |

|

|

Voltage parameter |

380v,50Hz, 3 phase |

|

|

Hydraulic oil |

46# hydraulic oil |

|

|

Gear oil |

18# hyperbolic gear oil |

|

|

Shaft diameter |

120mm |

|

|

Shaft Material |

40Cr, quenching and tempering |

|

|

Rack |

Gantry type (Memorial archway type) |

|

|

Rack material |

Nodular cast iron |

|

|

Punching die material |

SKD11 |

|

|

Rack quantity |

18 rows |

|

|

Drive mode |

Gear box drive |

|

|

Working speed |

about 1 piece/min |

|

|

Transmission mode |

Each rack with a gear distribution box drive |

|

|

Forming roller |

GCr15, quenching, the hardness of HRC56-62 º |

|

|

Motor power |

45 KW *2 Siemens brand |

|

|

Machine color |

Machine base |

As required |

|

Rack and gear box |

As required |

|

6. After-sales service :

1) . User manuals / videos on installation, adjustment, setup and maintenance of the machine will be provided.

2). The machine is with Wi-Fi function, our technicians will help to work if the machine has a problem.

3). when the borders are open, we will send technicians to your factory for training. (The cost is paid by the seller.)

4). Warranty 2 years (Excluding man-made damage)

5). Delivery time: 90 working days.

6). Machine price: contact us.

7.About Us :

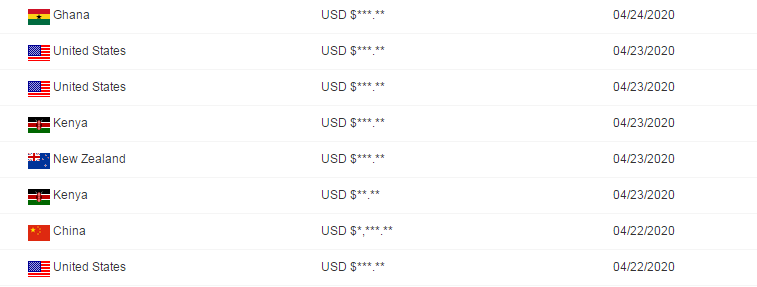

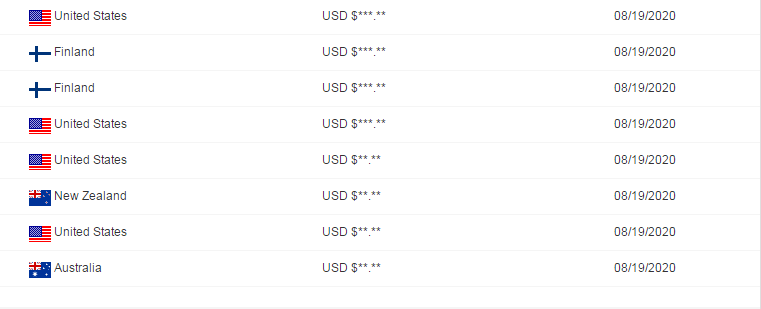

8.Transaction history :

Product detail pictures:

Related Product Guide:

We insist on offering good quality generation with very good business enterprise concept, honest income as well as best and fast assistance. it will bring you not only the premium quality product or service and huge profit, but probably the most significant is usually to occupy the endless market for Original Factory Silo Body Corrugated Plate Production Line - Grain bin silo stiffener making machine – Thomas , The product will supply to all over the world, such as: Barbados, United Arab emirates, United States, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Please your inquiry for more details or request for dealership in selected regions.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!