High definition Grain Bin Corrugated Plate Production Line - Grain storage silo corrugated sidewall machine – Thomas

High definition Grain Bin Corrugated Plate Production Line - Grain storage silo corrugated sidewall machine – Thomas Detail:

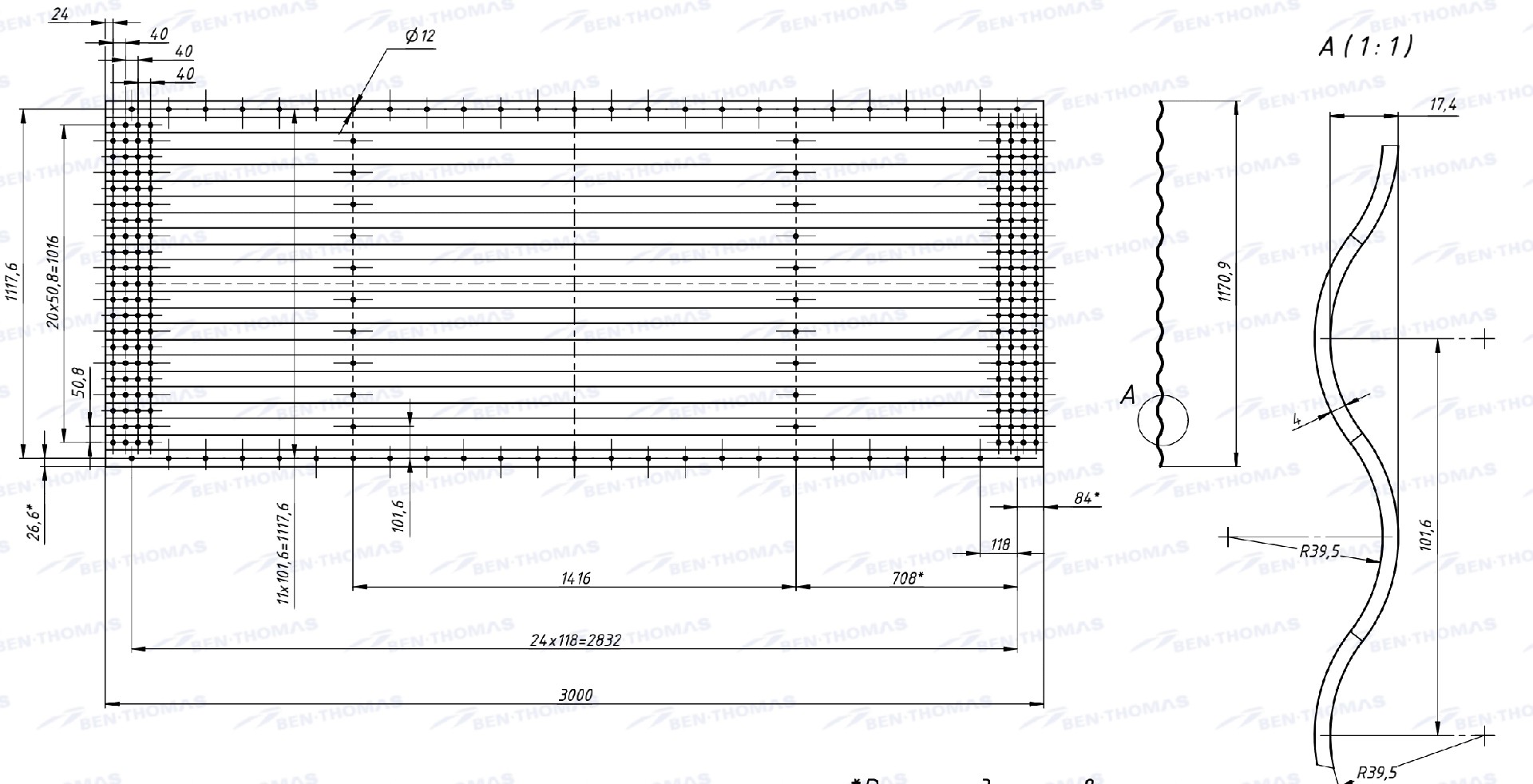

1.Drawing of the profile of the silo panel:

(Machine can be customized according to your needs, the following picture is the drawing provided by our customer, for reference only.)

2.Finished Product:

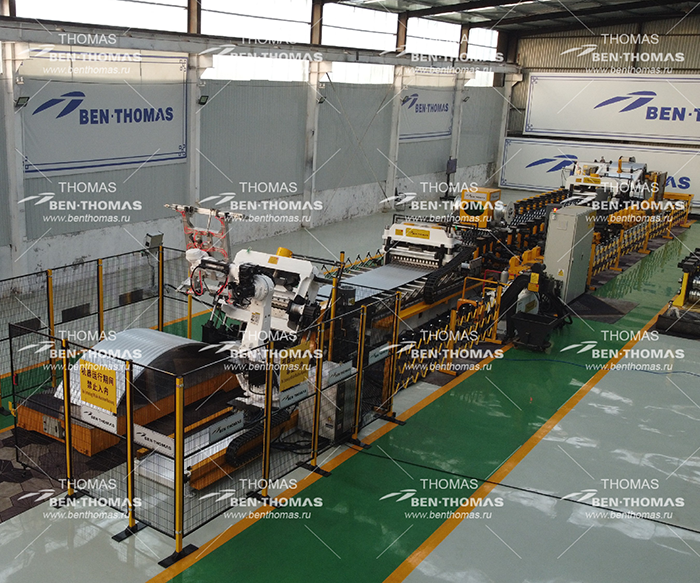

3.Working process of the production line:

Hydraulic decoiler –Shovel head device(Auxiliary feeding +Leveling) –Pre Cutting–Roll Forming Machine–Slitting & Waste Wire Collecting–Movable Pallet–Servo Movable Punching–Movable Pallet–CNC Bending–Hydraulic Cutting–Receive Table

4. Machine Pictures:

5. Machine Details :

|

Description |

||

|

Production name |

Silo Panel Forming Machine |

|

|

Machine floor area |

About 25.5m*2m(L*W) |

|

|

Feeding direction |

left in, and right out |

|

|

Voltage parameter |

380v,50Hz, 3 phase |

|

|

Hydraulic oil |

46# hydraulic oil |

|

|

Gear oil |

18# hyperbolic gear oil |

|

|

Shaft diameter |

140mm |

|

|

Shaft Material |

40Cr, quenching and tempering |

|

|

Rack |

Gantry type (Memorial archway type) |

|

|

Rack material |

Nodular cast iron |

|

|

Punching die material |

SKD11 |

|

|

Rack quantity |

22 rows |

|

|

Drive mode |

Gear box drive |

|

|

Working speed |

about 1 piece/min |

|

|

Transmission mode |

Each rack with a gear distribution box drive |

|

|

Forming roller |

GCr15, quenching, the hardness of HRC56-62 º |

|

|

Motor power |

45 KW *2 Siemens brand |

|

|

Machine color |

Machine base |

As required |

|

Rack and gear box |

As required |

|

6. After-sales service :

1) . User manuals / videos on installation, adjustment, setup and maintenance of the machine will be provided.

2). The machine is with Wi-Fi function, our technicians will help to work if the machine has a problem.

3). when the borders are open, we will send technicians to your factory for training. (The cost is paid by the seller.)

4). Warranty 2 years (Excluding man-made damage)

5). Delivery time: 90 working days.

6). Machine price: contact us.

7.About Us :

8.Transaction history :

Product detail pictures:

Related Product Guide:

We normally believe that one's character decides products' quality, the details decides products' high-quality ,while using the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for High definition Grain Bin Corrugated Plate Production Line - Grain storage silo corrugated sidewall machine – Thomas , The product will supply to all over the world, such as: Cyprus, Borussia Dortmund, USA, We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

We have been looking for a professional and responsible supplier, and now we find it.