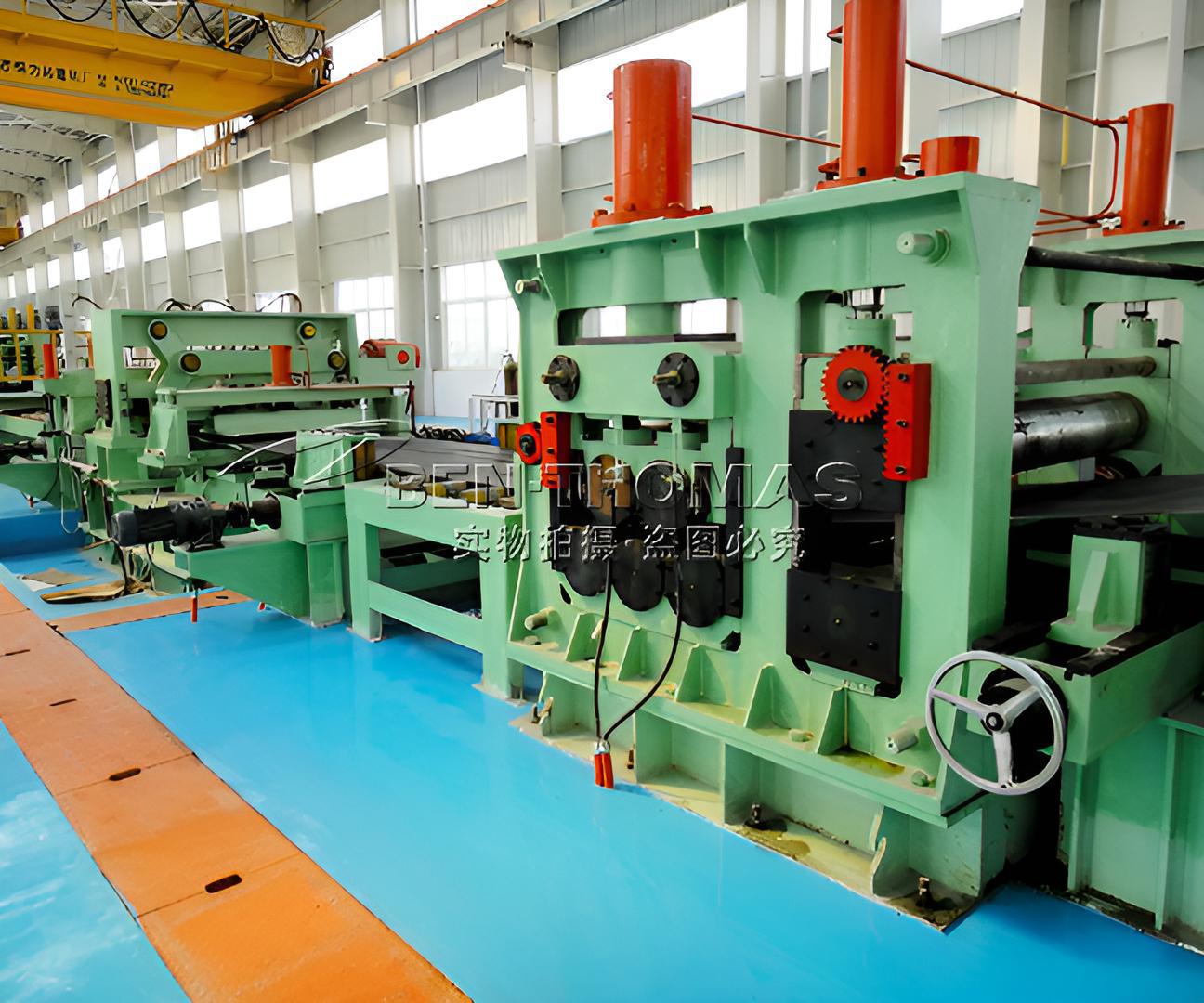

Cold Roll Forming Line For Metal Sheet Pile

Write your message here and send it to us